This type of building is the most popular way of private housing in Western Europe and Scandinavia, – regions that are close to Latvia by the climate, natural conditions and customer taste. Prefabricated houses have increased in popularity due to economical and ecological reasons as well as their practical characteristics.

Construction speed and quality

Prefabricated houses – both standard and individual projects – are produced industrially, within workshop conditions. This ensures the quality of the selected timber structures and individual parts are constructed rapidly.

An important advantage of prefabricated buildings – the building can be placed on a wide range of foundations ranging from both home projects and plot geotechnical conditions. There can be used corner element foundations, screw pile foundations, slab foundation, concrete foundations, etc. The modern technology has the ability to provide maximum thermal efficiency of the building and build them much faster than conventional houses, it also eliminates the need to wait for the foundation to set (harden) as it’s in the traditional method. Moreover, the assembling on building particular site does not require extra time and the use of heavy construction machinery. This significantly reduces the total project cost, which is important to the customer and it protects the environment. Experience shows that a comfortable house for a reasonable price can be constructed, from design to finish, during one summer season.

Practicality, Safety and Ecological thinking

Prefabricated houses are comparatively cheaper than other types of buildings in their construction and operation. It is characterized by excellent thermal insulation and lower cost of the heating season regardless of the type of heating. These buildings are designed and constructed with all of the EU requirements and safety standards. They are fireproof, and are not jeopardized by an aggressive environment factors (humidity, different termites, rot, etc.). It is important that the prefabricated houses provides the inhabitants with a comfortable microclimate. Buildings naturally “breathe” during the summer it has a pleasant coolness, while in winter it is easy to keep the heat in. Natural building and thermal insulation materials that are used gives the indoor wood a natural aroma, as well as provides the house owners with a natural non allergic environment. Finally – prefabricated buildings do not necessarily require a capital foundation. This is the only type of buildings that is legal in different areas of conservation, where the current state law prohibits capital construction.

Diverse architectural and design options

Prefabricated building technology allows for a wide range of customer request fulfillment in appearance of the building and the creation of planning and interior furnishing. It is not difficult, if necessary; to add new elements of construction to the existing building – various extensions, such as terraces, roofs, verandas, etc.

We offer a modern design, functional, high quality wooden modular house. Available in both standard and individual projects, these houses are relatively fast to build and, moreover, do not require a long project coordination.

Houses are constructed using only ‘’green’’ wood components, eco woodworking tools and eco insulation. Wooden walls “breathe” and radiates heat, thus the house is healthy and with a pleasant microclimate aura.

Modular house construction is a rational compromise between the need to save money and ensure maximum practicality and comfort in the building. In today’s conditions in many parts of the world these types of buildings are widely used as individual structures (residential houses, garden houses, and summer houses), public buildings (offices, shops, and commercial pavilions) and industrial buildings (garages, warehouses, manufacturing workshops).

Modular type combines the needs of the owner and the conditions of the building site. The modular themselves are made of wood or the so-called standardized sandwich panels with high strength and insulation with already built in communications (electrical, heating and water supply systems, sewage and air conditioning equipment).

An important and valued customer advantage of modular house is their mobility. They are quick to assemble and do not require any additives capital foundations. In addition, if necessary, modular home are equally quickly dismantled and installed in a different location.

Of course, architectural form of modular house is limited to the individual project and other technologies reclaimed houses, but the skillful use of a variety of architectural and design solutions (glazed facades, skylights, Tambour, shutters, terraces, verandas, lamps, decorative wooden elements, sound wood modern paint, etc.) and modular homes can assign individuality, originality and elite look.

Modular wooden house “HARMONY”

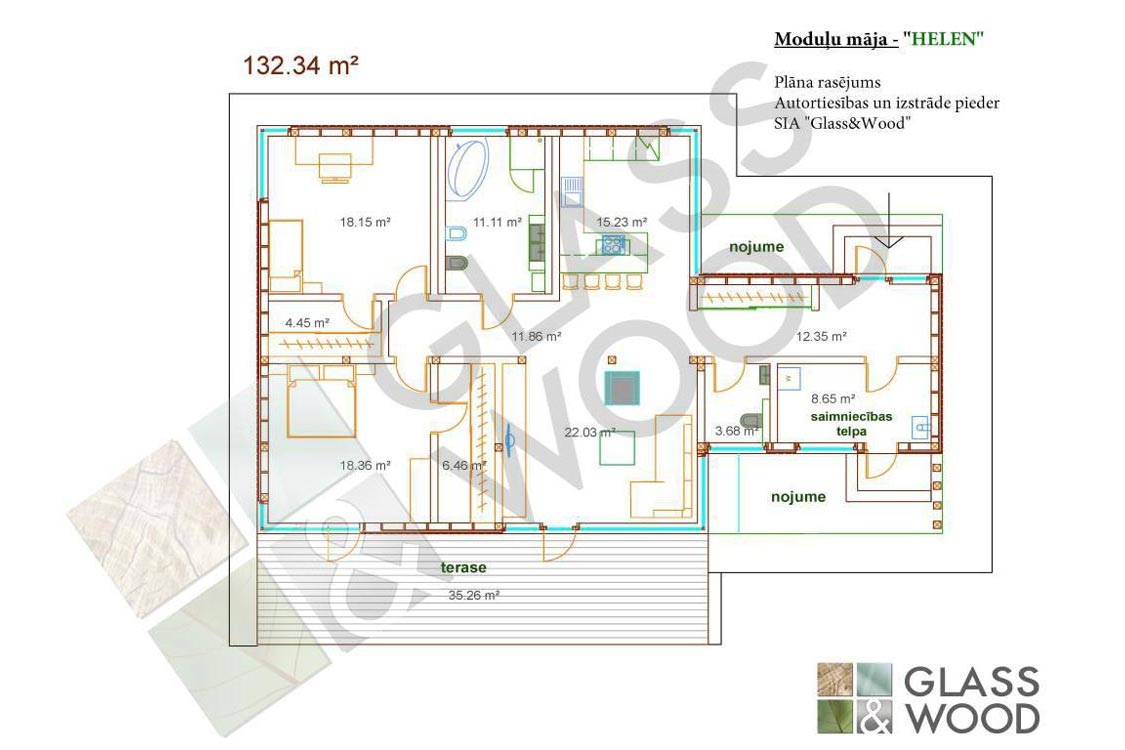

Modular wooden house “HELENA”

Nowadays, there are various construction methods for both, wooden and concrete, houses. Our company designs, engineers, coordinates projects, and constructs timber frame houses. Parts of timber frame houses are made in the factory and then transported to the location.

For frame buildings we use wood, because it is a natural and living material which has sufficiently low thermal conductivity, so the house is protected from heat. Unlike conventional plank wooden-framed houses, the construction of timber frame houses doesn’t require a continuous seam for connecting planks, and is able to withstand relatively high loads.

Our experts will help you to navigate the frame house construction details and make the right choices that will give you the opportunity to enjoy the natural, pleasant home for the next 80 to 90 years.

We offer to create for you your own personal design, and we will adapt to the requirements of the building. We are ready to develop the project from your individual sketches or just a description that you give us, so you will save money on redundant frame ordering.

Advantages of frame houses:

- Thanks to the innovative technology, assembling is possible at any time of the year, as well as other works that does not affect the quality of the material;

- Construction time of the house does not exceed 3-4 months;

- Due to the fact, that parts of frame houses are made from softwood with a moisture content of 15%, after assembling the houses dose not settle. So, right after assembling, it is possible to build finishing and prepare to move to a new house!;

- The timber frame construction does not require to purchase of bulky, expensive basis, because timber frame houses comparing to brick and concrete houses, are light;

- In construction of frame houses heavy equipment (cranes and excavators) is not used, which means that you will save money on renting such equipment;

- Frame homes are universal, because you can build external design as your heart wishes, it can look like any style house. Universal dimensions of components allows to use a variety of materials for finish construction, both internal and external finishes.

This technology enables designers to realize even the bravest projects.