House foundations are part of the house under the ground, which hosts the house and exposure time. You can say that it has a thick bottom layer.

Strip foundations – it is a concrete structure, which runs along the entire perimeter of the house. These foundations of construction under all load-bearing walls, maintaining the same basic cross-sectional area. Strip foundation construction technology is relatively simple compared to the screw pile foundations.

But this plea requires a lot of work and invests a large material consumption compared to pilar type bases (large amounts of concrete, more templates, mandatory use of the crane). Strip foundation recommended for waterproofing, as well as insulate them. Can also build the foundations of concrete blocks, for example, using “FIBO” blocks.

Strip foundation may be used:

- For house with concrete, stone, brick walls (with a density greater than 1000 to 1300 kg / cubic meter);

- For house with severe divisions (monolithic or prefabricated reinforced concrete, metal);

- Where threatens the basis of lumpy soil compaction layers;

- If it is planned on the ground floor or basement, as this band basis simultaneously performs two functions – the foundation and walls.

It is very important to choose the right type of foundation for when the house is being planned for construction. It is recommended that you choose a professional who is considering all the factors and offers the most economical option to the soil.

Classification of strip foundation:

Monolithic strip foundations

Monolithic strip foundation construction and installation is time-consuming and complicated process. Although it is no secret that the ribbon properly installed bases, are safe, resistant to aggressive environments, as well as house design provides a solid foundation. To monolithic strip foundations wouldn’t erode and concrete mass should be smooth, they should be installed professionally.

Nevertheless band technology is the basis for the world are popular because these bases are highly resistant to forced large loads. Using this type of foundation, the walls can be constructed from concrete, concrete blocks and bricks. These basics can build only in a stable, durable soil.

As with all types of foundation, and this is the cons – it requires a lot of construction material consumption, a lot of time rebuilding errors is difficult and expensive.

Prefabricated strip foundations

Prefabricated strip foundations consist of rectangular or trapezoidal blocks. Before construction is sift the sand 10 cm thick layer, on which are laid in concrete blocks. Blocks in the construction of the ranks, it takes the load of the building, which is spread over all the blocks. Blocks to construct the foundations only to determine the total load of the house, because the strength is limited.

We also offer exponent strip foundation – decorative concrete blocks.

Column type foundations – a great invention. This type of foundation is economical as it is consumed in a smaller amount of material, but at the same time provide the necessary load-bearing capacity. Properly constructed type column bases are as safe as the ribbon and concrete block foundations. It is a good choice for economic construction as the basis for laying no need to order concrete mixers, the supply of which the object is often paid large sums.

Foundation installation is not complicated, it requires a small concrete mixer, shovel, ruberoid, a little reinforcement and physical work.

Foundation pros:

- It is not necessary foundation molds, it is a great time-saving;

- Ground and main contact area is less than other types of foundation;

- Material savings;

- Comparatively, less to land a job.

With a small surface area is taken the necessary time.

Foundation and basement wall insulation use waterproofing membrane, whose range is very wide. Differences between them are manufacturing material, thickness and properties. Of your choice and assembly quality depends on how your house will be resistant to moisture.

Insulation shall be chosen, taking into account the moisture conditions. Constructively, they are:

- Moisture insulation (low humidity) – used in buildings, which is impermeable to water the soil above the groundwater level. Insulation is protected from surface water, capillary leakage, as well as from the natural soil moisture.

- Waterproofing (medium and high humidity) – used to protect the house from the surface water to flow into the house, the house of high groundwater areas and buildings where the floor level is high humidity. Also used in swampy areas which are visible danger that water can accumulate in the foundation walls and basements.

Roofs main function is to prevent the ingress of moisture inside, at the same time providing good ventilation and water vapor diffusion from the inside to the outside.

Roofing require Protan PVC waterproofing membrane, because tipical roofing dose not provide protection against moisture. Effective results, the membrane must be fixed properly, as well as the roofing and roof repair works must be carried out carefully. Damaged membrane does not provide full protection in place through the fault of water flows through the film. So that the roof does not start to rot – we recommend this important work to entrusted professionals.

Polymer membrane roofs and their main advantages:

- Long life to the roof surface;

- Resistance to permanent UV rays;

- Resistance to fire;

- Resistance to root infestation and micro-biological effect;

- Possibility to move over the surface (with feet);

- Suitability for mechanical strengthening against wind effects;

- Complete gluing to the surface in order to facilitate the possible leak localization;

- Partial bonding to the elevation of wind;

- Low cost, fast installation and work on the details;

- There will be no ceiling perforation (possible leaks, noises, does not allow construction);

- Full range of application;

- Compatibility / resistance of bitumen;

- Resistance to low temperatures.

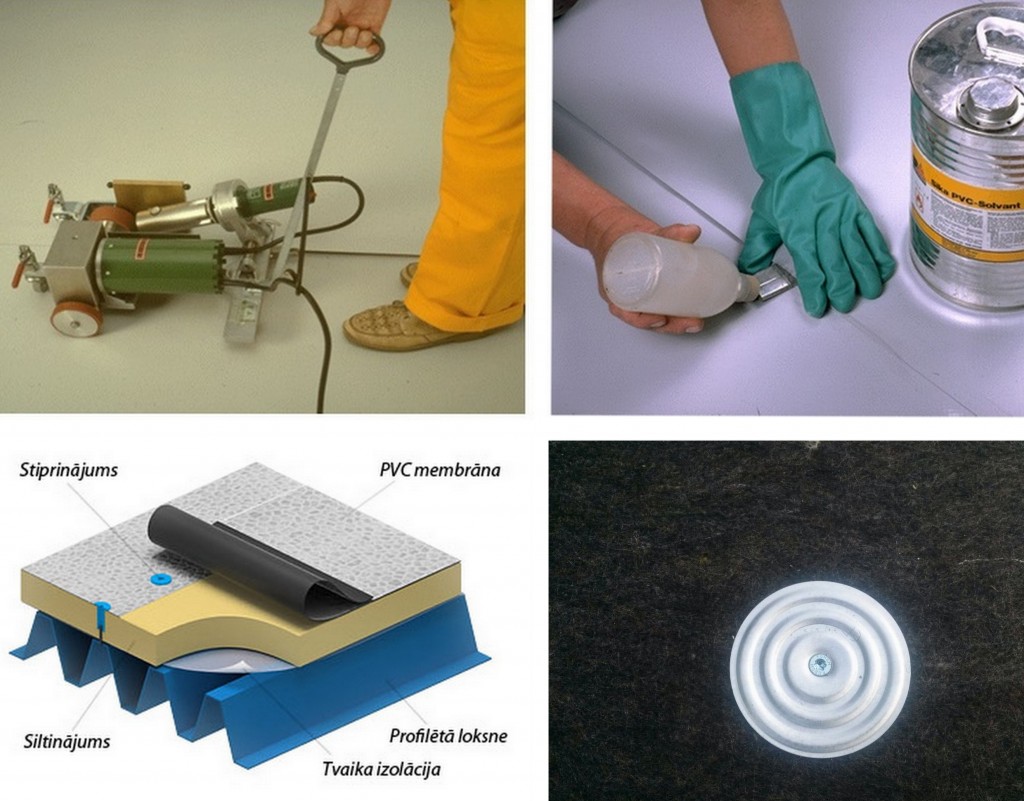

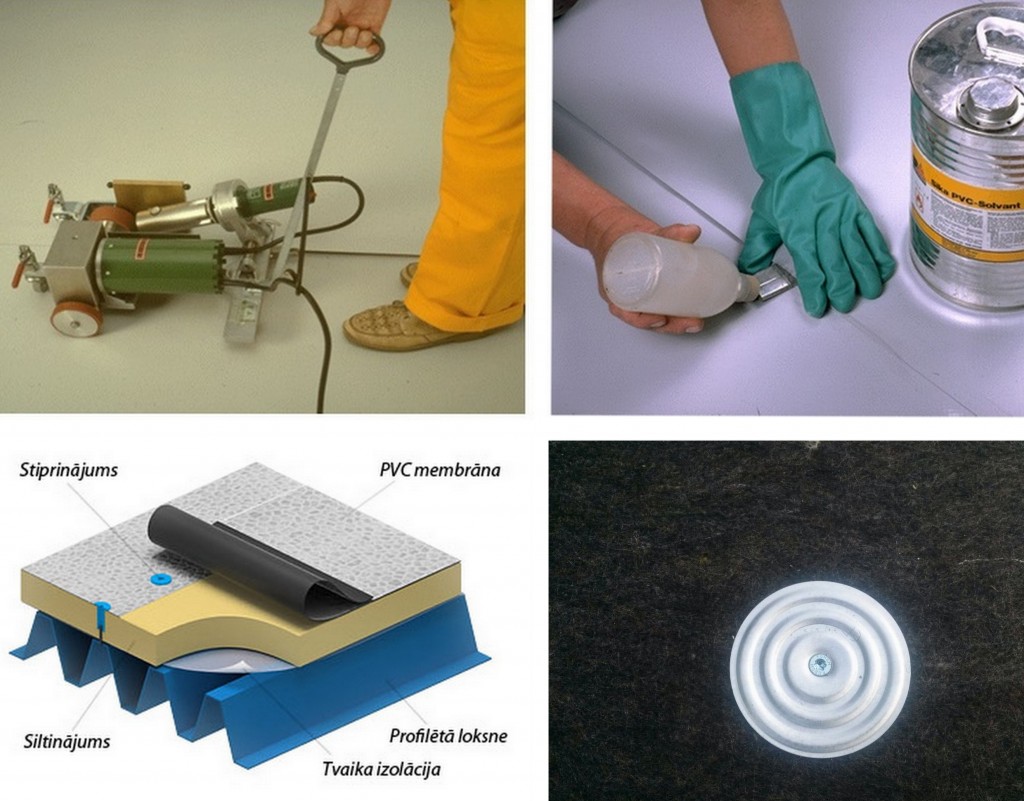

Mechanical Strengthening

The membrane is strengthened through the roof intended for that special dowels and cut to the desired configuration and wavy SikaTrocal steel / PVC sheets (Type S and SG).

Glue Strengthening:

Roof waterproofing membrane Sikaplan SGK is glued using polyurethane glue SikaTrocal C-300th

Press Strengthening:

Beneath the soil, pebbles, paving and so on, is used for waterproofing roof membrane Sikaplan SGMA as strengthening material through ballast weight.

Advantages of Sika PVC membrane :

- Fireproof – During installation, we do not use an open flame thereby excluded a risk of fire, as well as enabling the incorporation of sites with a high degree of fire hazard;

- Membranes are self extinguwishing. Fire class E according to EN ISO 11925-2, EN 13501-1. External Fire Safety (Part 1-4) BROOF (t2), BROOF (t3) <10 ° EN 13505th;

- Incorporation – PVC membrane systems are installed in a single round and with the width of 2m, compared with bitumen systems provide significantly faster incorporation. Membrane installation can be made in almost any environment up to -10 C;

- Resistance – Especially our climatic conditions developed membrane Sikaplan VGWT retain flexibility even at -25 C (according to EN 495-5), as well as allow for roof operation (eg .: snow, icicle cleaning). PVC membranes are resistant to root infestation and micro-biological attack.

- Membranes available in bright colors, which provides solar heat reflective effect in reducing the cost of operation (eg: air conditioning and ventilation costs).

Sikaplan membranes have high water vapor diffusion rates, without providing additional venting of water vapors, thus not concentrate moisture insulation, which worsen the thermal insulation characteristics, as well as damage to the building structure.